Architectural design processes and workflows are traditionally driven by functional requirements and structural hierarchy of materials. Nature on the other hand, is impartial to the complex sequences of the synthesis of materials that integrate in a coherent process of morphogenesis. Despite the revolution in computation aided design and interdisciplinary upgradations in the digital fabrication technologies, architectural design processes fail to acknowledge the machines, tools and processes used for fabrication. The realization of specific fabrication processes and their individual constraints often lead to amendments to an already established workflow by making desperate adjustments to rationalize the design.

Our goal is to introduce design processes which are based on the knowledge of the fabrication tools and which incorporate material properties, constraints, tolerances, machine limitations and interactivity inside it. Those intentions and strategies are embedded inside the design workflow through a series of algorithmic strategies for interactive simulation, optimization and digital fabrication of architectural projects in 1:1 scale. Advanced computational tools open new possibilities and demonstrate a precise construction logic from early design stages, having control of cost.

Research Areas

Segmentation

Structures

3dp Shells

We work in the intersection between mesh relaxation processes and weighted meshGraph representations as design tools for the fabrication and construction of self-sustained minimal shell structures and branching topologies. Biological stripe pattern morphologies are used as a construction logic. We use machine learning to predict an optimal pattern organization balancing structural and fabrication criteria. We specialize in tools oriented to discretization free form surfaces, especially for CNC flat materials with good cracking resistance, high bending fatigue life, light weight, good toughness, as Polypropylene (PP), or similar.

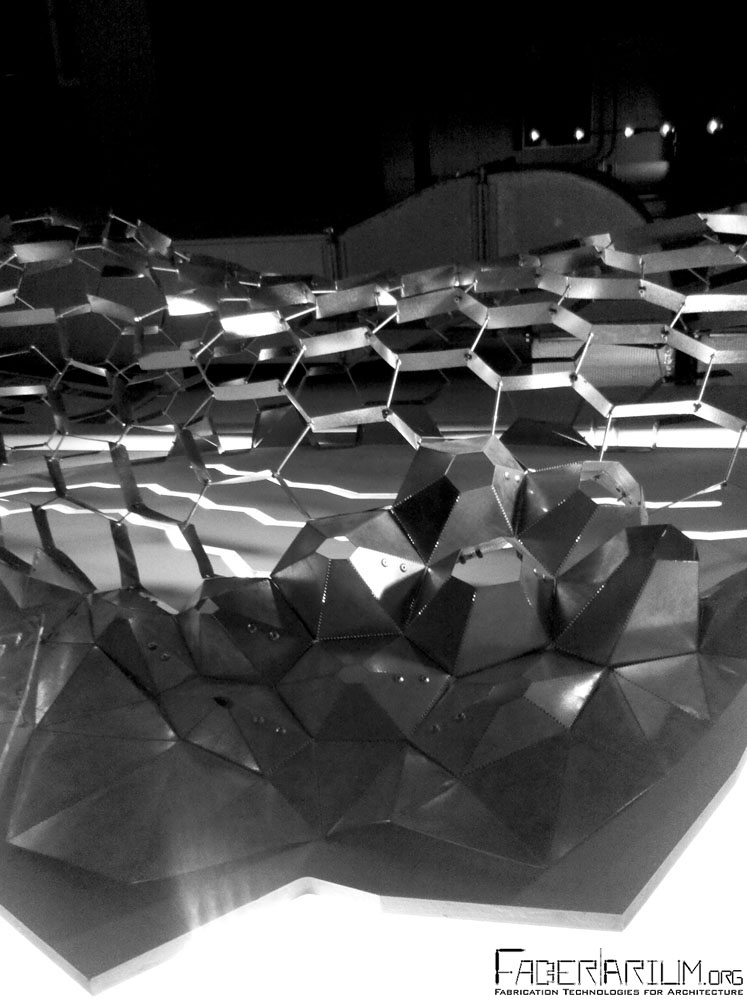

We specialize on the design and construction of 1:1 scale pavilions like vault structures and facade systems using Particle Spring system for Dynamic Relaxation and connection system which are easy to assemble and disassemble. We explore the material usage of wood, aluminum profiles and ACPs where the typical roles of cladding and support structure are reversed.

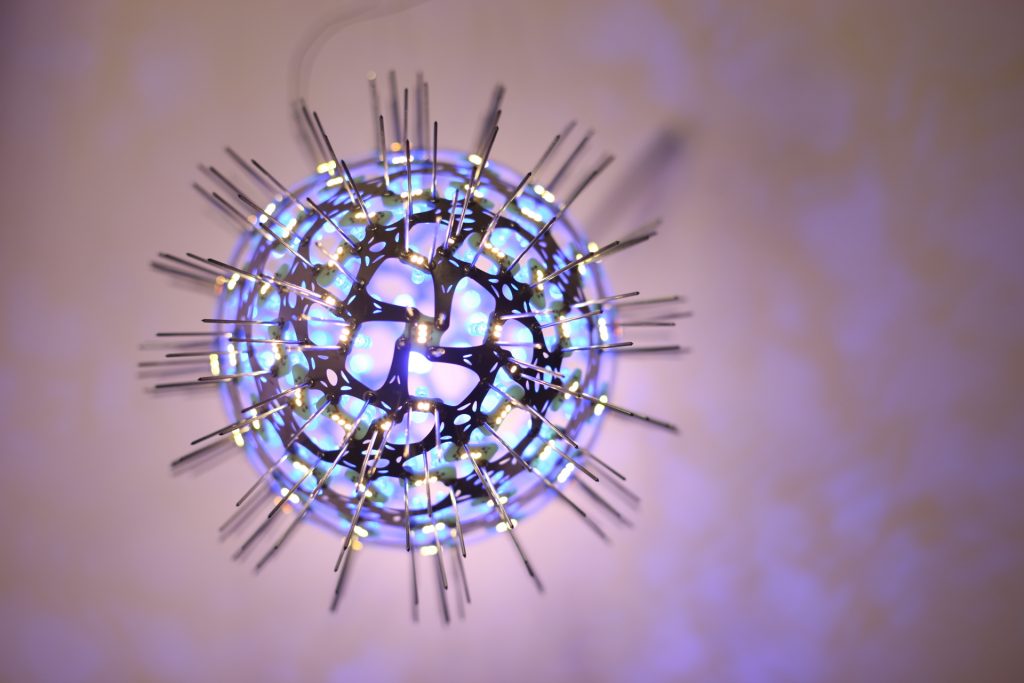

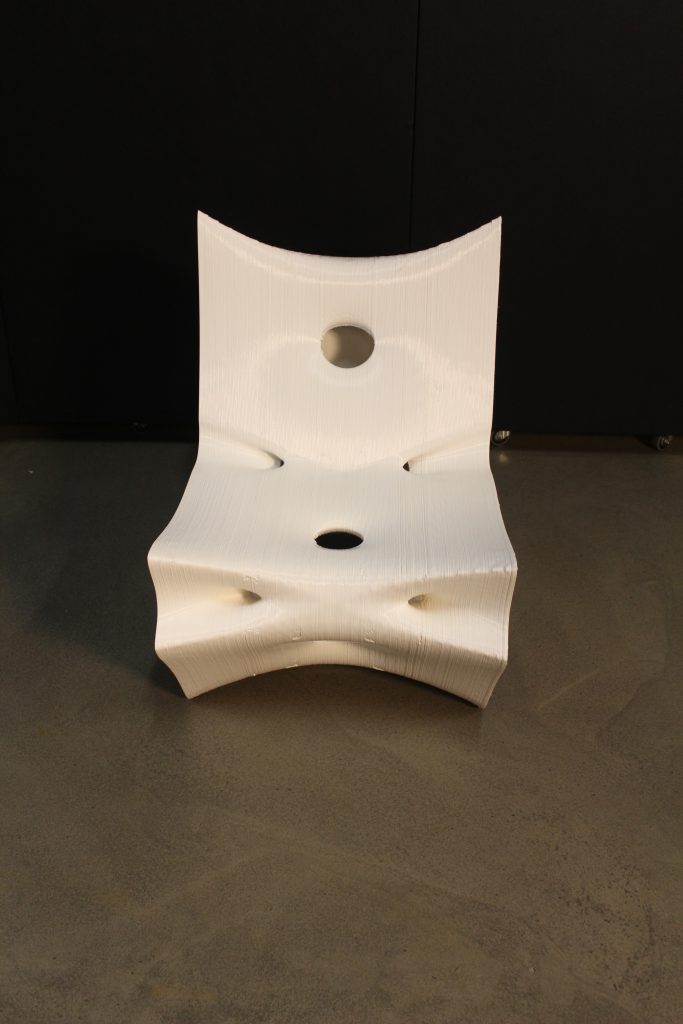

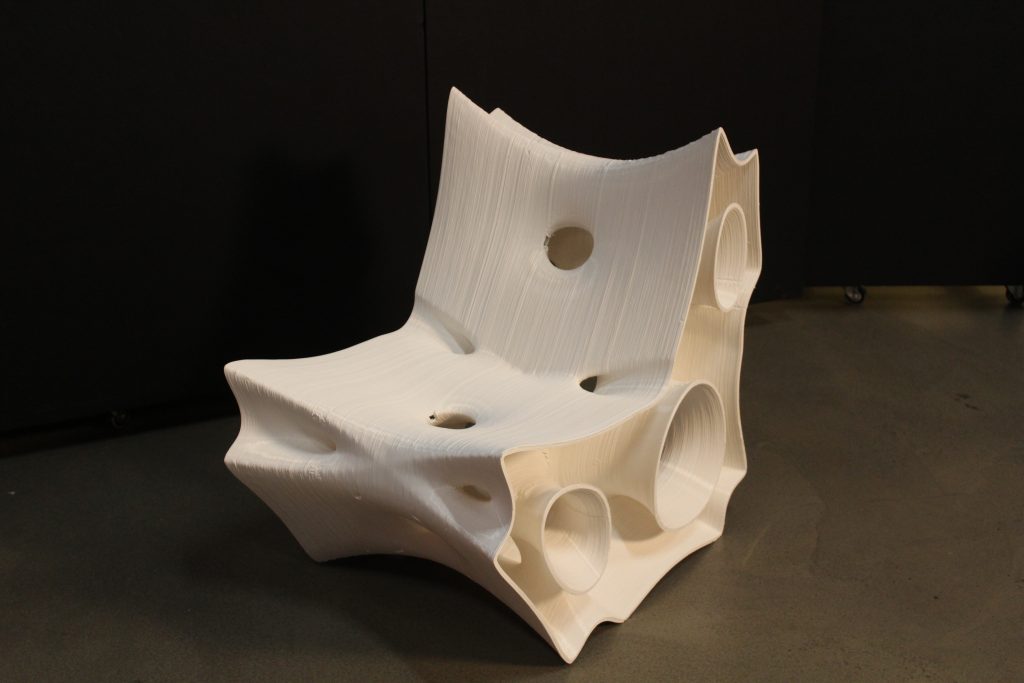

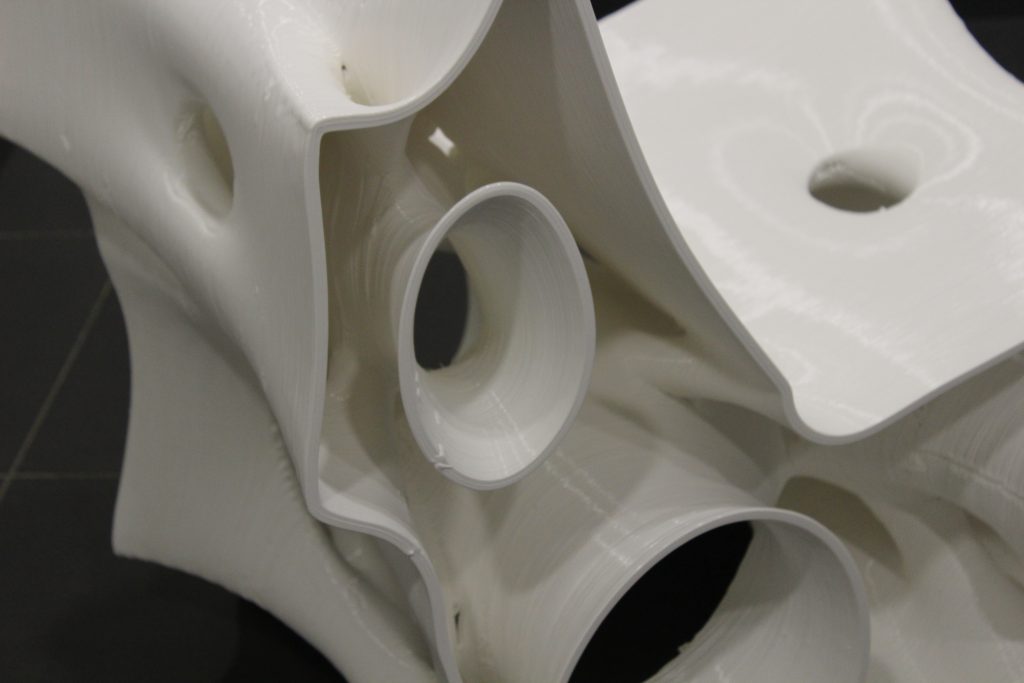

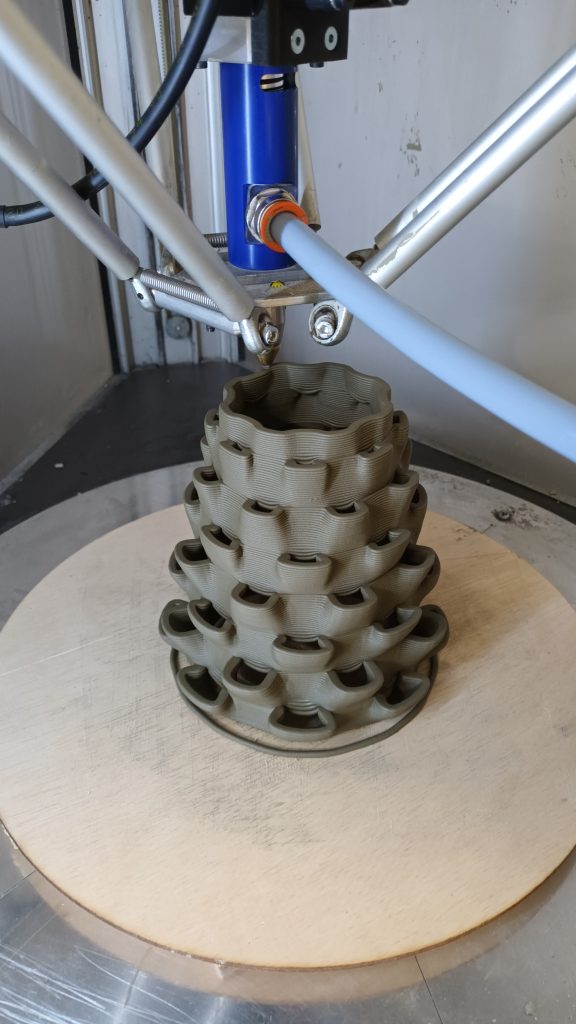

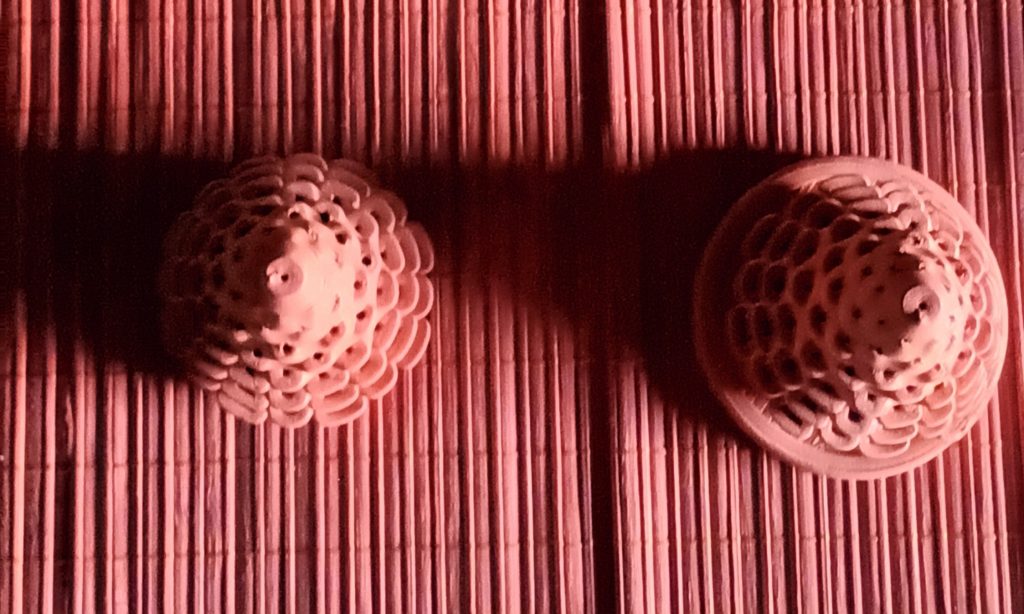

Responding to the challenge to design for additive manufacturing (AM) rather than 3D print a design, the fabrication method and materiality establish the design constraints that inform the geometry. We specialize in designing and optimizing a product together with its production system to reduce development time and cost, developing a generative design process for large scale additive manufacturing of thin shells or hollow structures like furnitures, lamps, interior walls.

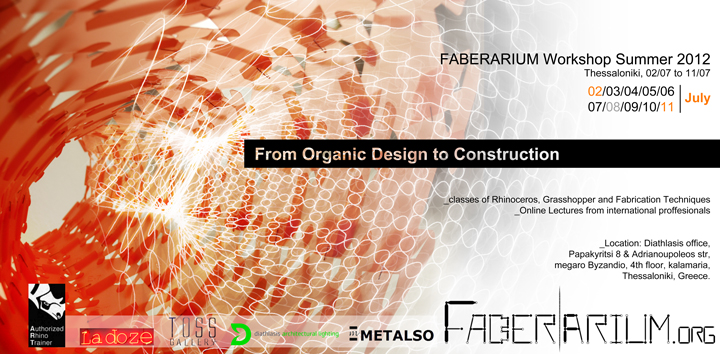

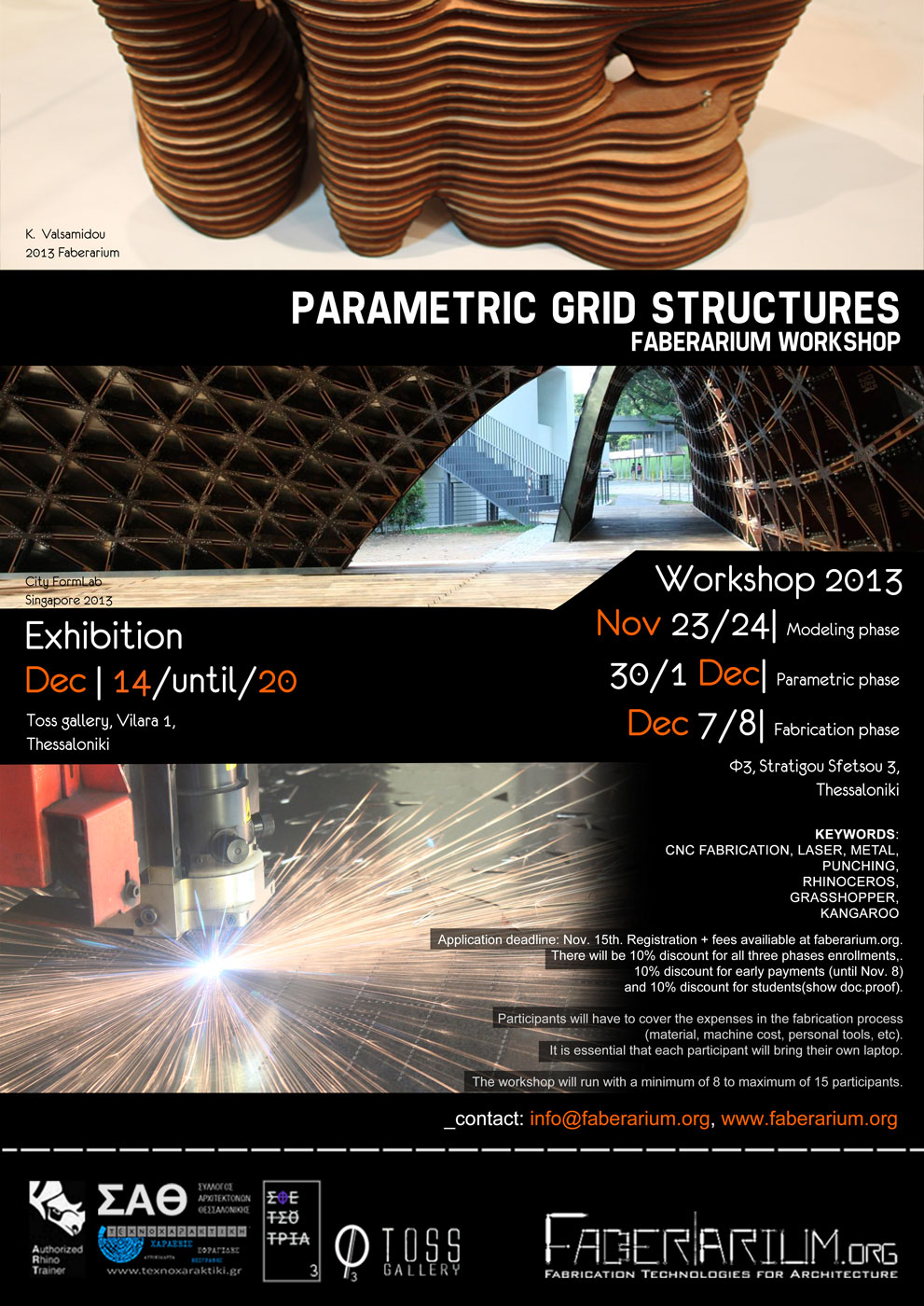

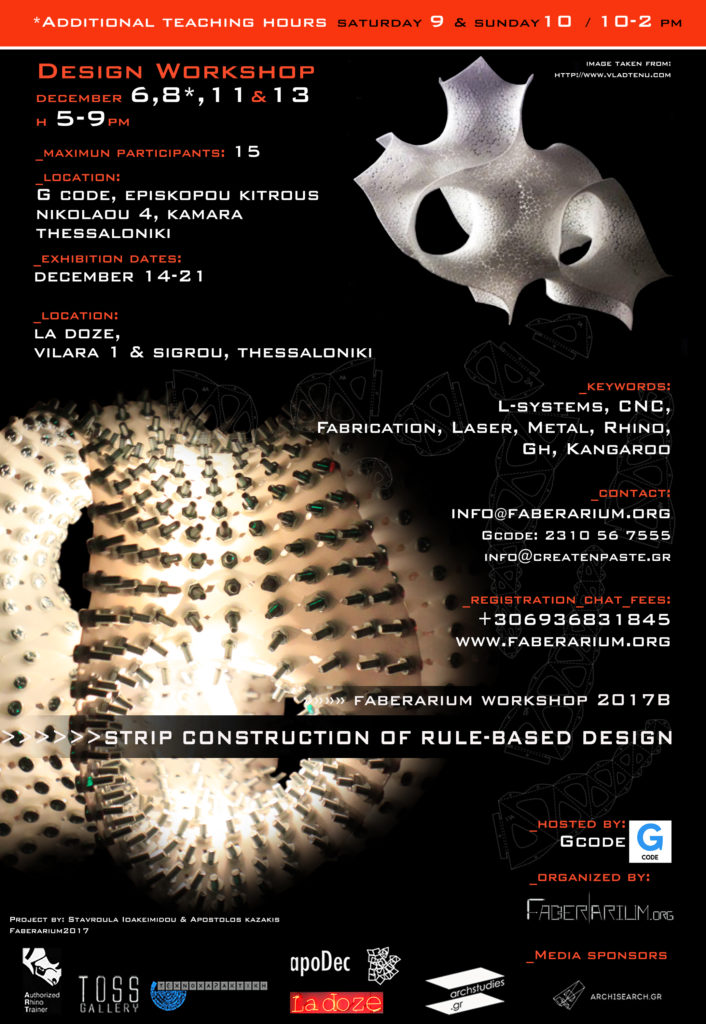

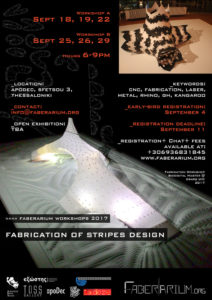

Workshops

A platform for experimentation in the evolution of architectural education, computational design logic and construction.

During the workshops participants have the opportunity to sharpen their modelling and prototyping skills, to experiment with a range of digital production tools, and to design a unique set of components that negotiate a range of material gradients across a field condition. Through iteration, participants generate and assemble components (parts) to form a larger network (whole).

The goal is to combine technological precision and pedagogical creativity. Participants understand in early-stage concepts, design strategies, material constraints and machine limitations. Using parametric and programmable computing tools they transform complex 3D geometries and structures into construction elements obtaining a sense of fabrication time and material costs depending on complexity.

—

Exhibitions

—

Publications

- Giannopoulou E., Baquero P., Warang A. and Estévez A. T. (2019) “Stripe Segmentation for Branching Shell Structures – A Data Set Development as a Learning Process for Fabrication Efficiency and Structural Performance”, in J.P.Sousa, et al. (eds) Architecture in the Age of the 4th Industrial Revolution: Proceedings of the eCAADe+SIGraDi joint Conference 2019, Porto, Portugal, September 11-13, 2019.

- Giannopoulou E., Baquero P., Warang A. and Estévez A. T. (2020) “Machine Learning Approach For Biological Pattern Based Shell Structures”, chap. pp.79-83, in S. Bartolo et al. (eds.), Industry 4.0 – Shaping the Future of the Digital World, CRC Press, Taylor & Francis, Boca Raton. London, 2021. eBook ISBN 9780367823085.

- Giannopoulou E., Baquero P., Warang A., Orciuoli A., Estévez A. T. and Brun-Usan M.A. (2019) “Biological pattern based on reaction-diffusion mechanism employed as fabrication strategy for a shell structure”, in IOP Conference Series: Materials Science and Engineering, 471 (9), IOP Publishing Ltd. doi:10.1088/1757 899X/471/10/102053 (Scopus) link